Inhaltsverzeichnis

The development of tanning in the next 25 years as influenced by legislation 1999

Dr Heinz-Peter Germann, Director, Lederinstut Gerberschul Reutlingen, Germany

There is a tendency towards a more harmonised approach in the setting-up of new regulations or Standards on industrial processes and products. This is a result of an increased international co-operation in politics, especially througlr the process of European Unification. This means that the actual Situation of the industry at different locations will need presenting with great care to ensure fair treatment.

However, a more global approach to environmental protection seems to gain acceptance. The idea of a sustainable development should be used in its best sense for the benefit of both the global environment and the continuation of the mainly small and medium sized enterprises in the leather industry.

The ecological balance sheet for manufactured goods

In future, the use of terms like „eco“, „bio“ or „natural“ in the marketing of leather (products) for commercial considerations only, will be restricted. The increasing amount of information as a result of future research in the field of ecology will be better understood and more accurately interpreted by the public authorities. So, for instance, investigations on ecological balance sheets for different technologies in leather production will enable an environmental assessment in a realistic manner.

Among other things, this will illustrate that neither synthetic tanning or auxiliary agents should be considered as generally „bad“ nor natural products as generally 'good1. All ecological effects resulting from the production of diese agents, up to their remaining portions in final products and wastes have to be taken into consideration.

The effects of Legislation and consumer perception

Biodegradability: chrome leathers and alternative tannages

Chrome tanned leather is very stable with high temperature resistance and virtually complete resistance to bacterial decay. Simple biological breakdown is not possible.

Other tanning Systems will biodegrade, and this has become a marketing feature in certain sectors, especially parts of the automotive sector.

Alternatives to landfill for discarded consumer goods has huge momentum. The recyding of paper, glass, metals, plastics, wool and cotton etc. is commonplace, but pending European legislation is beginning to reshape basic manufacturing philosophies.

The concept of the automotive that is fully recyclable at the end of its useful life is already established, and it is spreading to other areas of manufacture. The electronics industry is evaluating the logistics of consumer goods out, followed by receipt for disassembly and recycling. It is considered by leaders in these sectors that responsibilities for disposal will ultimately be directly linked with the manufacturer. This raises the possibilities of rental of goods in a dosed manufacturing-recyding loop as opposed to purchase. Responsibilities thus remain with the manufacturer -with attendant responsibilities forced upon the suppliers.

Re-usability is already established as a concept by the consumer, or biodegradability where appropriate. These options as opposed to simply dumping discarded items have become powerful marketing tools and can shifr the consumers perception of the acceptability of a product.

This fact needs careful attention by the leather sector. It is, for example, already being stated in the promotion of certain polyurethanes that automobile upholstery made from these products can be broken down into basic molecules all ready for reuse.

However, although vegetable tanned and specialty leathers may biodegrade, these leathers do not provide the properties that are required in the main leather spectrum.

Major replacement of chrome tannage does not appear a viable Option. Serious consideration is therefore needed in the re-processing of leather artides at the end of a useful life.

'Old' leather - shoes, dothing, upholstery, leathergoods - may be converted into new outlets via the leatherboard Option. It is also technically easy to produce a hydrolysate although oudets are restricted due to contamination.

Energy recovery may also be viable as methane produced from the hydrolysate by an anaerobic bacterial breakdown, or by direct pyrolysis/gasification of the discarded leather products.

Serious research is needed. These disposal routes may never be cost effective, even as the price of raw materials rise, or the cost of tipping becomes prohibitive. Legislation and consumer pressure for a dosed 'environmental loop' may force uneconomic options to process 'old' leather artides. The cost of a dean and acceptable public image will be a low price to pay to maintain a healthy and viable industry.

Integrated pollution prevention and control

With a view of environmental Performance, future legislation will focus on die idea of an integrated pollution prevention and control. More and more, people will become aware of the senselessness of shifting the problem of waste water loading to the field of solid wastes generation. In this respect unnecessarily rigorous effluent Standards need careful consideration.

Production-integrated water use

Fresh water is becoming rare in many parts of the world. The objective of reducing the water consumption in leather producdon will be driven by either restrictions on use and/or rising charges. These factors will therefore form an essential part when considering production-integrated measures.

On the other hand, water being an important transport and reaction medium will be indispensable to the tanneries. Moreover, for reasons of environmental protection and safety at the place of work, water has already substituted organic solvents in certain areas. In degreasing and parts of finishing, water use has increased instead of being replaced itself. In addition, washing processes at the end of the wet operations will gain in importance. This is because the portion of extractable matter in the leathers will have to be kept at a minimum to meet the regulations and Standards on consumer goods that can be expected in the future.

A decrease in water consumption therefore seems to be feasible only by the application of an effective water-recyding. It is most likely this will be based on the recovery of selected process and wash liquors. The end-of-pipe treatment will be limited to those effluents that are unsuitable for an efficient and practicable recyding.

Regulating salt emissions

Another example which calls for production-integrated measures is the reduction in total dissolved solids(TDS). This is increasingly targeted through regulations in many countries, especially those with a lack of fresh water resources. In these countries the use of treated effluents within agriculture is already indispensable.

The apprehension concerning the worlds fresh water resources will lead to more stringent regulations in this field.

Tanneries, therefore, will have to find a way to control the TDS emission. Since elimination from waste water by purification techniques appears unreasonable, process technologies permitting an efficient reduction in the use of salt will have to be developed fiirther.

This will result in an increasing portion of hides and skins being processed in a manner to avoid the salt curing process, and in the reinvesdgation of salt-free pickling Systems. Additionally, with the help of the chemical industry, new process chemicals and auxiliaries with higher concentration of the active components, hence less salt content, will have to be developed.

The incineration of chrome containinq leathers and sludqes

Simple incineration (municipal) is not an Option where chromium containing compounds are present. Leather wastes - shavings, trimmings and buffing dust, 'old1 leather artides and chromium sludges, need controlled conditions to prevent the formation of hexavalent chromium.

A number of routes are available for treating these solids, the basic equipment being established for treating other industrial solid wastes and municipal sludges.

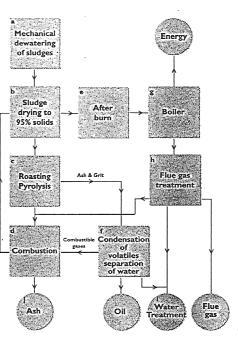

The schematic is therefore very general and there are many possible permutations; attention is shown to airborne emissions and treatment of waters used for scrubbing the gases.

Before processing, the waste must be dry, so any sludges must be mechanically dewatered, then force air dried to an acceptable moisture content. Breakdown of the solids by roasting in the absence of air produces combustible volatiles and avoids the formation of Cr(VI). Combustion with excess air forms Cr(VI), but it is possible, using silicate additives, to fuse this ash as insoluble granules, thus avoiding any leachate. Alternatively the extraction of the soluble dichromate for regeneration is possible. Energy recovery either as combustible gas or heat are practical options.

- Stages can be avoided if solids are dry.

- Pyrolysis/ gasification of organic matter in the absence of oxygen.

- Combustion of residual material with minimum amount of air and controlled temperature to avoid Cr(Vl) formation.

- Combustion of waste gases to remove remaining carbonaceous material.

- Non-condensable volatiles used as fuel in combustion process or for power generation: condensates after Separation from water similar to light fuel oil.

- Heat recovery following after-burn.

- Removal of grits by cydone and scrubbing of gases for removal of hydrogen halogenides, sulfur dioxide, NOx and aerosols.

- Water used for scrubbing operations • requires treatment.

- Ashes for Special disposal, possible extraction of Cr, or fusing into an insoluble granulär ash.

Figure 1

Publication:

H.-P. Germann, The development of tanning in the next 25 years as influenced by legislation 1999, World Leather 12, 11/1999, No. 7, p. 8-9

Reference:

Kategorien:

Quellenangabe:

Zitierpflicht und Verwendung / kommerzielle Nutzung

Bei der Verwendung von Inhalten aus Lederpedia.de besteht eine Zitierpflicht gemäß Lizenz CC Attribution-Share Alike 4.0 International. Informationen dazu finden Sie hier Zitierpflicht bei Verwendung von Inhalten aus Lederpedia.de. Für die kommerzielle Nutzung von Inhalten aus Lederpedia.de muss zuvor eine schriftliche Zustimmung (Anfrage via Kontaktformular) zwingend erfolgen.

www.Lederpedia.de - Lederpedia - Lederwiki - Lederlexikon

Eine freie Enzyklopädie und Informationsseite über Leder, Ledertechnik, Lederbegriffe, Lederpflege, Lederreinigung, Lederverarbeitung, Lederherstellung und Ledertechnologie