Inhaltsverzeichnis

Improving the cover of light spot in the dyeing of aniline-type leathers 1997

Dr. Heinz-Peter Germann, Lederinstitut Gerberschule Reutlingen, Germany

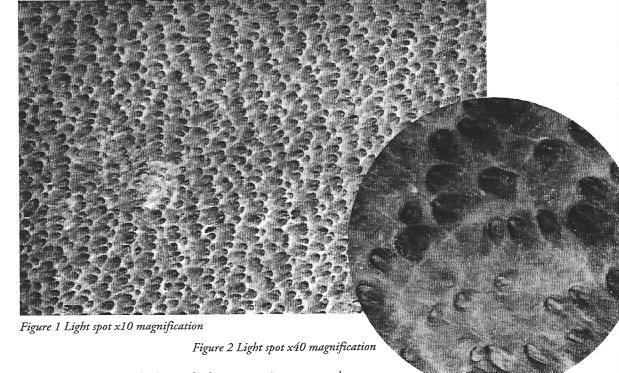

Figure 1 and Figure 2:

Only a small proportion of hides are completely free from grain damage and suitable for use as so-called 'natural nappa leather' in the field of upholstery leather.

Over a period of years an increasing incidence of the skin defect known as 'light spots1 has been observed. These are small circular changes of the grain structure, some only the size of a pin head, which are often undetectable even in the semi-finished State.

Usually this defect is observed after dyeing when these areas appear in the form of light coloured 'specks'. According to research and observations made from practical application, it appears that this phenomenon develops during the lifetime of the animal. The most likely cause is due to inflamed primary or secondary infection in the papillary layer of the skin following an infestation of ectoparasites such as trichodectes or lice.

Observations of this defect using the light and electron microscope show damage to the upper layer of the grain in the area of the 'light spots' as shown in Figures 1 and 2. These damaged areas stand out particularly clearly after dyeing, thus reducing the leather utilisation in high quality products and representing a considerable loss.

Investigations were made that might improve the quality where this defect was present, and these investigations concentrated on wet post-tanning processes including the use of drum pigments.

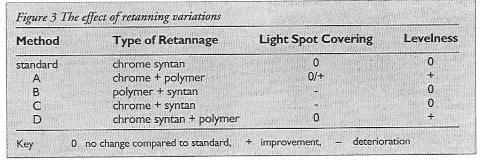

Figure 3:

The effect of retanning/dyeing techniques and drum pigmentation

The intensity and spread of light spot damage in the affected skins used in the investigations varied considerably, so the methodology used half hides the counterparts of which were processed as a Standard process for comparison. A medium brown shade was selected and comparative assessments were made after wet toggling, milling and dry toggling.

- These assessments concentrated on both light spot concealment and the levelness of dyeing.

- Various retanning combinations applied to wet blue stock (see Fig. 3) revealed that compared with a chrome syntan retanning process used as control:

- an improvement in the degree of levelness of dyeing was produced by the combination of a chrome tanning agent with a polymer tanning agent (A) and the combination of a chrome syntan with a polymer tanning agent (D);

- a deterioration in light spot concealment occurred by using a combination of polymer tanning agent and syntan (B) and chrome tanning agent and syntan (C).

A second series of variations based on diese findings was investigated and it was found that:

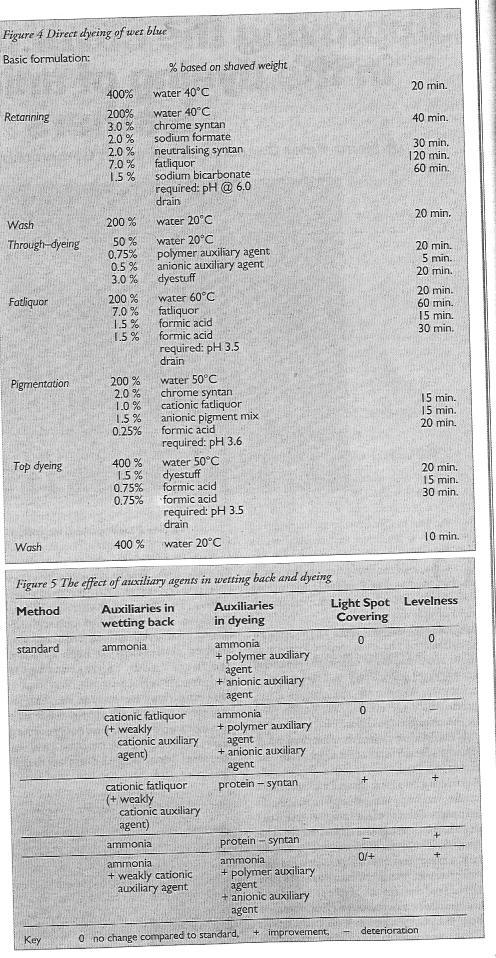

- a marked improvement in cover resulted by using a drum pigmentation System in a fresh float between through and top dyeings. For optimum defect concealment it proved advantageous to run an amphoteric polymer auxiliary agent ahead of the through-dyeing process, and an example of the basic recipe is given as Figure 4;

- no improvement resulted by using a polyadduct-based auxiliary agent or an acrylate binder followed by a chrome syntan before top dyeing;

- an unacceptable deterioration in levelness resulted by partial use of dye before neutralisation, although there was some improvement in the cover of light spot.

It was also considered that the uptake of dye in areas affected by light spot might be influenced by reduced wettability. For this reason, various anionic and non-ionic fluorine surfactants were used for possible improvements. The investigation showed, however, that there was no improvement in dyeing behaviour in these areas. On the contrary, there was an undesirable change in the feel of the leather with a marked increase in dryness.

Figure 4 and Figure 5:

Dyeing crust leathers

The investigation induded the dyeing of leathers after an intermediate crust drying (see Figure 5) and advantages were found when:

- a cationic fadiquoring agent was used when wetting back either on its own or in combination with a weak cationic auxiliary agent;

- a protein syntan was used in the subsequent dyeing process;

- a very weak cationic auxiliary dyeing agent was used with ammonia during wetting stage.

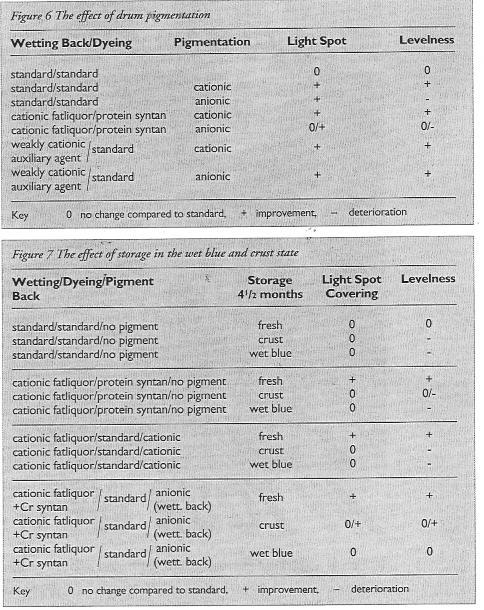

It was found that the application of drum pigments brought a marked improvement in light spot concealment when dyeing crust leathers. These results were similar to findings from dyeing wet blue leathers. Good results were achieved both with anionic and cationic pigmentation, and it was found that the applications could be made before top dyeing, in the same iloat, or in a fresh float after top dyeing (see Figure 6).

For pigmentation to be successful, however, it was found that:

- the shade of the pigment mixture has to match the shade of the dyeing;

- an excessively deep shade of the pigment mix can create an over-emphasis of the light spots and other open defects, and also lead to an irregularity of the surface colour;

- careful adjustment of pH value is essential.

The influence of dye selection

The characteristics of dyestuffs were also investigated and three brown dyes of different types - acidic, 1:1 and 1:2 metal complex dye - were tested in a variety of promising recipe variations.

In these investigations the 1:2 metal complex dye proved by far the best product in all the dye recipes used, induding the Standard recipe for both dyeing of the light spots and levelness. The effect of using this particular dye was of greater significance than the recipe used, highlighting the significance of dye selection. It must be remembered, however, that although the dyes were of different types, the findings should not be taken as a general guide to the behaviour of these three casses.

Liquid dyes were also studied where there wasa series commercially available for comparison with the equivalent powder dyes. In general a richer surface colouration and greater brilliance was produced with the liquid dyes due to their higher reactivity.

The effect of the length of storage

As it was expected that the chrome complexes in the leather would alter with ageing, the effect of storage of leathers in the wet blue and crust condition was investigated (see Figure 7).

Figure 6 and Figure 7:

Both wet blue and crust leathers were stored for four-and-a-half months, after which the wet blue was processed to the crust. The dyeing results of both of these „aged“ leathers were compared with crust leathers manufactured directly from fresh wet blue material. The following details were observed:

- differences in concealing light spots were minimal between the three different types of crust stock;

- there was a significant reduction in levelness with the aged leathers. With both types of crust, the dyeing result was lighter and showed a green-yellow hue compared with the fresh crust leathers. In several cases, the levelness had to be rejected as totally unacceptable;

- the crust leathers made from the aged wet blue demonstrated in many cases even poooresr results than the aged crust leathers. It was only by wetting back with the addition of a chrome syntan to make the leather more cationic, followed by anionic pigmentation, that it was possible to achieve an acceptable dyeing result.

The influence of wet blue characteristics

The investigations were performed on wet blue produced from a chrome-saving tanning process. To gain insight into the influence of the chrome tanning method, the best recipes from the dyeing investigations were applied to wet blue obtained from two commercially available sources. One supply was from completely cnventional chrome tanning process, the other from a high exhaustion, chrome tanning process (Baychrome-C method).

The dyeings from the high exhaustion method (strong cross-linking masking) demonstrated slightly less rieh colouration with better levelness compared with the more cationic wet blue. However, both types of commercial wet blue showed the same behaviour pattern as found with earlier investigations - with one exception.

Completely different results were produced from the drum pigmentation stage when shaded cationic pigments were used with a weak cationic auxiliary agent in the wetting back process.

With the conventional wet blue material there was a real emphasis of the grain damage. This was particularly noticeable in some open defects and chafed areas with emphasis of neck and grain wrinkles. In contrast, the same reeipe used with the wet blue from the high exhaustion chrome tanning method produced a beneficial result.

The effect of ageing was also observed with diese commercial leathers.

Crust leathers were made from the high exhaustion wet blue, and a deterioration in colouration of grain defects, levelness and brilliance was observed after a three-month storage period compared with freshly processed crust. These effects were greater than any advantages gained by improved dyeing techniques, but were assisted by drum pigmentation.

The same effects were noted with the conventional wet blue after a storage period of one-and-a-half months, and these findings confirmed the enormous influence of the storage period on the dyeing result.

Reducing the impact of light spot

It can be seen that there are a number of ways to improve the dyeing of aniline leathers and reduce the effect of white spot without affecting levelness. These include:

- Retanning using chrome-syntan + polymer

- Wetting back by incorporating cationic fatliquors and weak cationic auxiliary agents.

- Dyeing using

- amphoteric polymer or protein- syntan auxiliary agents;

- the „right“ selection of dyestuffs;

- possibly liquid dyes;

- by using matched cationic or anionic pigments as part of the dyeing process.

The shortest possible storage period from wet blue and crust stock. These methods can all help to conceal the problems of light spot and other surface defects. Good results, however, can only be gained by coordinated measures from the wet blue to final dyeing.

Reference

- Th. Schroer: Orientierende Untersuchungen zur Herkunft des Stippenschadens, Leder- und Hautemarkt 44 (15), P.8,1992.1

Acknowledgements:

Specialists from the chemical auxiliary agent industry and the association of the German Leather Industry as members of the working committee covering 'light Spots1.

Mr. T. Yaldir and the staff of the LGR involved in the research programme.

Ministry of Economics of Baden-Württemberg for financial assistance.

Publication:

H.-P. Germann, Improving the cover of light spot in the dyeing of aniline-type leathers, World Leather 10, 2-3/1997, p. 29-33

Kategorien:

Quellenangabe:

Zitierpflicht und Verwendung / kommerzielle Nutzung

Bei der Verwendung von Inhalten aus Lederpedia.de besteht eine Zitierpflicht gemäß Lizenz CC Attribution-Share Alike 4.0 International. Informationen dazu finden Sie hier Zitierpflicht bei Verwendung von Inhalten aus Lederpedia.de. Für die kommerzielle Nutzung von Inhalten aus Lederpedia.de muss zuvor eine schriftliche Zustimmung (Anfrage via Kontaktformular) zwingend erfolgen.

www.Lederpedia.de - Lederpedia - Lederwiki - Lederlexikon

Eine freie Enzyklopädie und Informationsseite über Leder, Ledertechnik, Lederbegriffe, Lederpflege, Lederreinigung, Lederverarbeitung, Lederherstellung und Ledertechnologie