Inhaltsverzeichnis

Ecological comparison of tanning methods (part 2) 2000

In the second of a two part paper, B Trommer from the Research Institute for Leather and Synthetic Leather Technology, Freiberg, and Dr H-J Kellert of the Leather Institute Tanner's School, Reutlingen, discuss work carried out at the institute which assesses the environmentai impact of different leather making processes

Changes in the production of a material for ecological reasons are only successful if the buyer accepts the incurred costs and the quality. Apart from the ecological issues, leather produced in an environmentally friendly way must not:

- have any extra processing problems

- must comply with all the appropriate

- physical specifications

- be easy to maintain

- fulfil any Special safety requirements (eg as regards flammability)

A high-grade product which lasts a long time will, in many cases, be superior to lower grade recycling products in its LCA as fax as consumption of energy and resources are concerned. This holds true, in particular, for furniture and car upholstery leather. Longevity as well as aesthetic criteria are important quality parameters for this material.

The leather quality has already been includedin the overall comparison of tanning methods (see figure 1 in December '99 issue) In the following text, parameters that are the utmost importance from the manufacturer's and consumer's point of view, will be detailed. To characterise the leathers, 46 testing methods were used to assess the true performance of tannages I - IV with regard to quality.

- The tests were subdivided into four different categories:

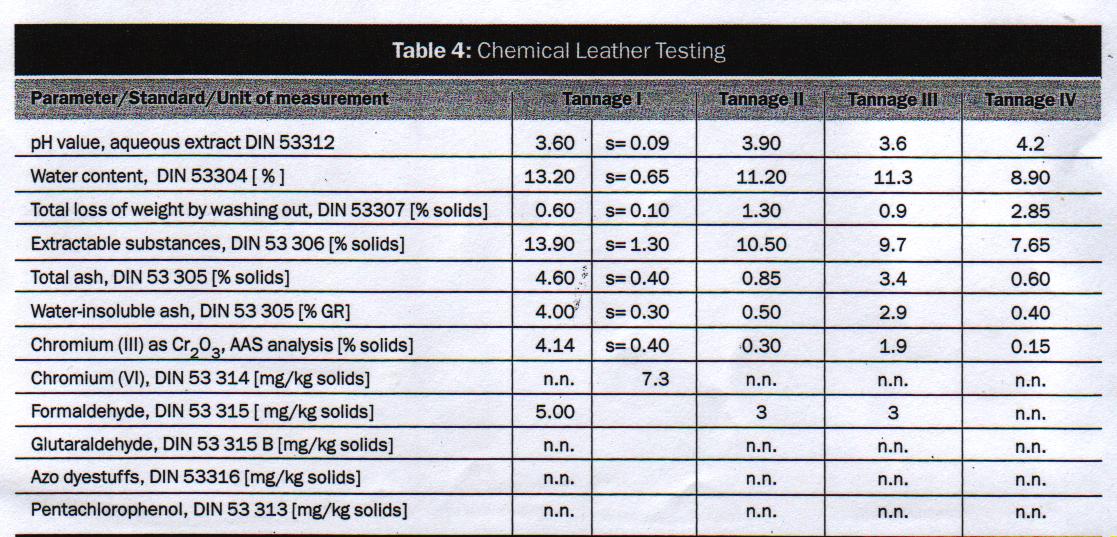

- chemical leather testing, table 4

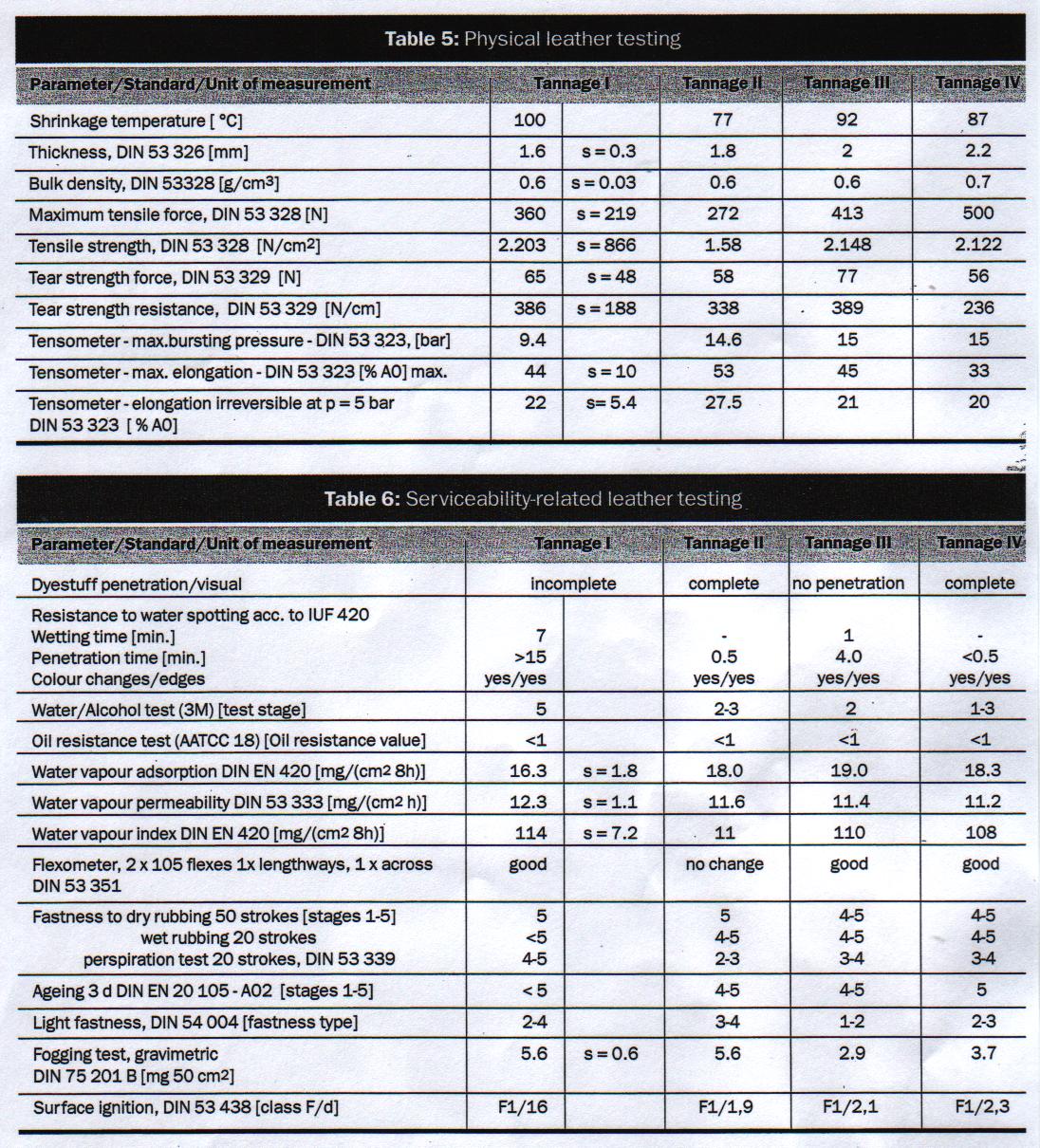

- mechanical-physical leather testing,table5

- physical tests on the leather, table 6

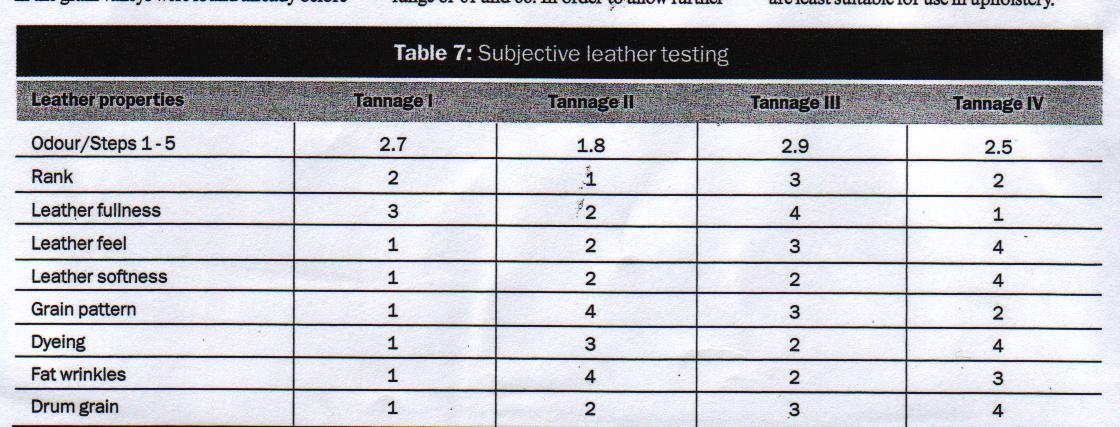

- test of organoleptic properties and visual assessment of the leathers, table 7

Standard test methods were used and in all cases the samples were conditioned in accordance with DIN 53303 Part 1 and were cut from the leathers, as far as possible in accordance with DIN 53302 Part 1 and Part 2.

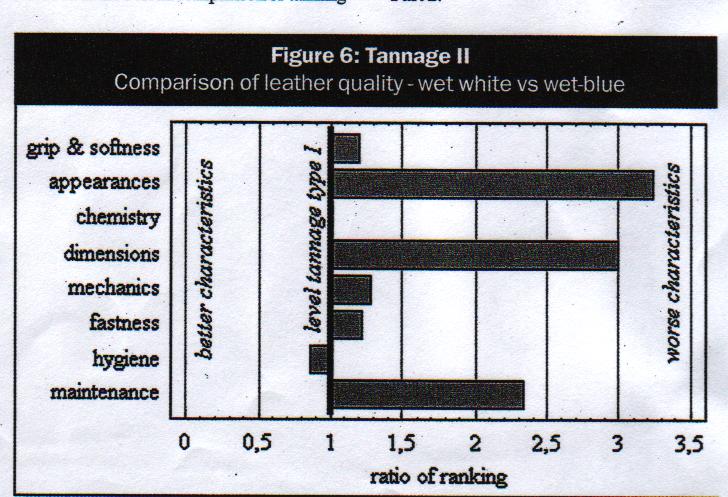

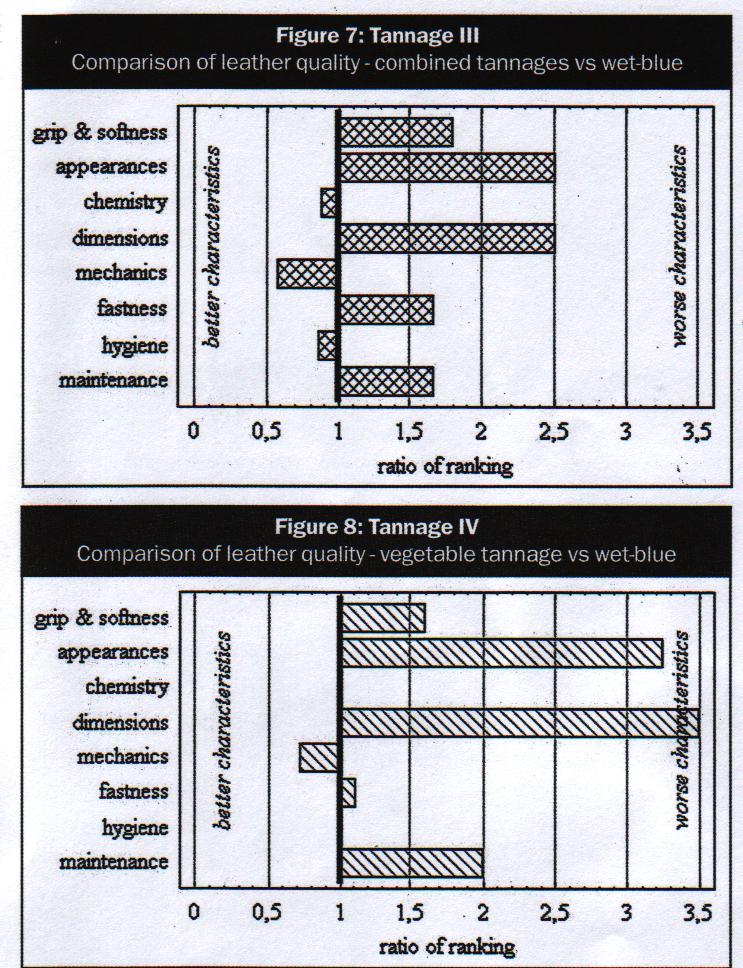

Figure 6,7 and 8:

Results

The testing of pH values of aqueous extracts yielded values between 3.6 and 4.2. These values are acceptable, in general, as a pH value of > 3.5 is normally required for upholstery leather. The same applies to the water content requirements for upholstery leathers. Although there are no direct requirements regarding the water content of furniture or car upholstery leather, a review of technical terms and conditions of supply shows that values of between 8 and 16%, sometimes even of 12-20%, are required. The total weightloss by washing out should be in the region of 7%, a value which was achieved easily by all leathers. Even the more stringent requirements, around 1.5%, which apply to shoe uppers are achieved, with the exception of leather produced with tannage IV.

With regard to the test value extractable substances, leather produced using tannage I is not as good, but remains within the acceptable range of 5 to 18%. All other tannages remain below these values. The same applies to the chrome oxide content which is naturally relatively high in the leathers from the control group, but remains within the acceptable range of 3 - 5.5%. The value targeted with combination tanning methods of at least 0.8% is reliably achieved by tannage III leathers.

As expected, the proportion of pollutants which may be present in leather such as pentachlorophenol, illegal azo dyestuffs and free formaldehyde or formaldehyde capable of being split off hydrolyticalry, was also below the values required by law or below the relevant detection limits of the method of analysis.

Table 4,5 and 6:

Tests for chromium (VT) on tannage I leathers resulted in one positive finding on a total of five leather specimens which was dose to the detection limit of the DIN 53314 method used. The value was confirmed three weeks later during a repeat test. After five months storage, no more chromium (VT) could be detected on this leather sample.

The values of 5 and 3 ppm for formaldehyde for leathers produced using tannages I -Ill coincide with experience gained from daily testing routines. The small quantities involved evidently result from leather auxillaries which are included in the relevant recipes.

The pollutants glutaraldehyde, azo dyestuffs, which can split off illegal amines, and pentachlorophenol, indicated in table 4, could not be detected. The limit values or detection limits still valid in Germany are:

- pentachlorophenol, 5 ppm. Higher values are forbidden

- an azo dyestuff isconsidered illegal if,in the course of its reduction (according to DIN53316), more than 30 ppm of certain aromatic amines can bedetected

- for aldehydes there are no limiting statutory requirements at present, but recommendations from test institutes lie in the range of between 150 - 200 ppm

Disregarding the fact that the leather substance, compared with normal upholstery leather; was generally too thick, this parameter also strongly indicates the influence of the tannage type. Although the shaving thickness of all tannages had been set to a finished substance of 1.1 mm, greater values were generally obtained.

With regard to their strength parameters, the leathers produced using tannages I - IV only showed slight differences and were within the acceptable range.

Table 6 gives an overview of the related test parameters. The dye penetration was assessed visually. Incomplete indicates that dyed through and not dyed throughzones alternated. Penetration is considered to be complete only if an homogeneous distribution can be achievedover the leather cross section. No penetration indicates that the dyestuff only dyed the grain and fleshside and did not penetrate.

Leathers from tannage I showed a better result in the water spotting test than leathers produced using the other tannages. The wetting and penetration time of the water spotting test correspond to a high grade upholstery leather, although the staining and edge formation must be judged negatively. A similarly good result was achieved in the water/alcohol test (3M test). The vegetable tanned leather presented a very poor result with regard to this parameter. The ranking assignment 1-3 indicates that the leather behaviour over the total surface area in this test was subject to large variations.

Flexometer

The term 'good' indicates that the leathers did not show any cracks in the grain surface before or after the flexometer test. The Statement 'no change' indicates that small cracks in the grain Valleys were found already before the flexometer test, with no change after the test, ie no increase in size. The rub fastness values for tannage 1 were also the best They fulfil today's requirements, while the leathers produced with the other methods clearly lag behind. The light fastness values required today of >3 on average are just attained by all tannages. All other values only differ slightly, but remain within the acceptable range.

The conclusions regarding the overall appearance of the leather surface are of particular importance for the assessment of the tannages. The assessment criteria include leather fullness, feel and softness, which can only be determined using organoleptic methods. However, in addition the grain pattern, the dye levelness, the appearance of wrinkles and the so-called 'drum' grain were assessed. This was carried out visually by comparing all leathers under the sameconditions.

No suitable test methods exist for any of these parameters today, with the exception of the measurement of the stiffhess in flexure, which can be used as an assessment criterion for leather softness. All criteria mentioned were assessed by experienced staff and the results are summarised in table 7. Rankings from 1 to 4 were assigned to distinguish the individual leathers. These figures are synonyms for the grades Very good, 'good', 'satisfactory' and 'poor'. Table 7 shows that leather produced in accordance with tannage I was assessed as better than the other tannages, with the exception of the parameters for leather fullness and odour.

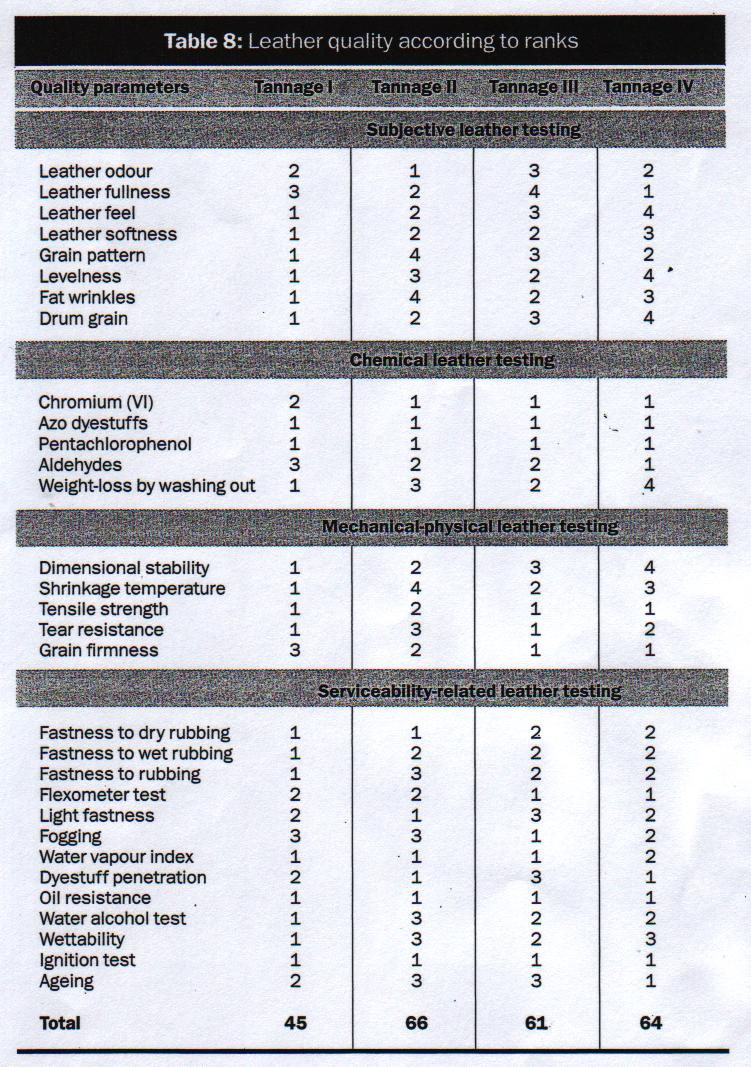

Table 8 gives an overall ranking for the tannages. This can be considered as an overall assessment of the diflferent tannages and their 'fitness for purpose' as upholstery leathers.

The quality advantage of the control group (chrome tanned leather) is unambiguous. The tannage was firstranked about twice as ftequentiy as leathers from tannages II - IV Unfortunately, the other leathers cannot be classified unambiguously according to their production. The sum ranks are within the range of 61 and 66. In order to allow further

distinction, the parameters were regrouped into eight groups with the following meaning/description were formed:

- appearance: grain pattern, levelness of dye, fat wrinkles, drum grain

- feel: leather feel, softness, fullness

- fastness: fastness to rubbing (dry, wet,perspiration), light fastness, dye penetration, ageing

- mechanics: tensile strength and tear resistance, tensometer, flexometer

- dimensional stability: equality of thickness, thickness, shrinkage temperature

- chemistry: chromium (VI), azo dyestuffs, PCP, aldehydes, total weight loss due to washing

- hygiene: odour; fogging test, ignition test

- soiling: water spotting test, 3M test, oil resistance test

For leathers produced with alternative tannages II - IV, the ratios relative to the control group were calculated and are shown in figures 6 to 8. The graphs should be interpreted in the following way: Values > 1 lie to the right of the baseline and signify a worse quality rating than the control group. Values around 1 demonstrate a leather quality comparable with that of the control group, and all values < 1 (left of the base line) show a better result than the control group.

The graphs show that leathers produced using the alternative tanning methods are comparable with the control group leathers in the chemistry, hygiene and mechanical categories. As far as appearance and dimensional stability and, to a lesser extent, soiling and fastness, are concerned, the leathers with the alternative tannages are inferior. Overall leathers produced using tannage 1 clearly occupy first place, followed by leathers produced using the chrome salt retannage (tannage III). Leathers tanned with tannage II occupied third place, while leathers produced according to tannage IV are least suitable for use in upholstery.

Table 7 and 8:

Conclusion

The results of the comparison can be summarised as follows:

- tannage I. The leather quality was significantly better than that produced with the other tannages. Several possibilities with adequate availability for recycling and material reuse of production residues could be determined. The disadvantages of tannage I included the contamination of the sewage sludge with chiomium and the related restrictions and problems in its agricultural use, incineration or landfill disposal.

- tannage II: The leather quality was generally unsatisfactory and the tannage demonstrated the lowest shrinkage temperature. For disposal of the leather waste, thermal methods are most suitable due to the eluate values, depositing in landfill or use for plant cultivation must be seen as questionable. Compared with the control group, no Solutions are available today for reuse of the leather waste.

- tannage III: The leather quality was satisfactory. The shrinkage temperature came dosest to the control group. Shavings from tannage HE gave the most favourable eluate values. The leather waste can be disposed of best in landfill sites, by thermal methods or through use in plant cultivation. However, the availability of practical methods using the waste is as unclear as that of tannage H The wastewater pollution by aldehydes was marked in comparison with other tanning methods.

- Tannage IV: The leather quality fell below that of leathers produced with the other methods. The pollution is mainly a quantitative problem. All untreated wastewatered showed a high organic load, when measuned against the sum parameters. The sludge probem became particularly evident when compared with the other. The eluate of the shavings also showed critical values.

The benefits of this tannage include leather, wastewater, sludge and waste from heavy metals and the possibility for using the leather waste as a raw material for leather fibre board. The use of the material plant cultivation and the possible thermal disposal of all wastes are further benefits. When the wastewater was treated according to the activated sludge process, positive synergistic nitrification effects occurred during the joim treatment of beamhouse and tanning effluents.

Overall conclusion:

The comprehensive experimental won demonstrated disadvantages of the alternative tanning methods which are not seen win chrome tannage. In practice, it is safe to assume that a chrome tanned leather produced in accordance with the 'Best Available Techniques' principle using the best proceses, including all environmental measures, undoubtedly be classified as environmental compatible. The indication of the tanning method in itself cannot be regarded as an ecological quality criterion irrespective of the leather article. If an environmental compability classification is to be assigned along tests for suitability, hygiene and pollutants, a independent assessment of the tannages and process conditions used during production imperative.

Acknowledgements:

The authors are very grateful to the Federate Ministry of Economics and Technologie (BMWi) for providing the project function through Working Group of Industrial Research Associations - AiF). The author would like to thank all staff involved at the Research Institute for Leather and Synthetic Leather Technologies and the Leather Institute Tanner's School, Reutlingen, for their comprehensive tests and analytical work.

The project also enjoyed the practical support of the development departments of the companies Salamander Industrie-Produkte GmbH and Chemische Fabrik Grünau GmbH.

The support of the members of the Leather Research and Environmental Committee of the VdL (Association of the German Leather Industry) and the Advisor Council Biopolymers of the FILK Freiberg, is also acknowledged.

Publication:

B. Trommer, H.-J. Kellert, Ecological comparison of tanning methods (Part 2), Leather 202, 1/2000, Nr. 3, S. 25-30

Kategorien:

Quellenangabe:

Zitierpflicht und Verwendung / kommerzielle Nutzung

Bei der Verwendung von Inhalten aus Lederpedia.de besteht eine Zitierpflicht gemäß Lizenz CC Attribution-Share Alike 4.0 International. Informationen dazu finden Sie hier Zitierpflicht bei Verwendung von Inhalten aus Lederpedia.de. Für die kommerzielle Nutzung von Inhalten aus Lederpedia.de muss zuvor eine schriftliche Zustimmung (Anfrage via Kontaktformular) zwingend erfolgen.

www.Lederpedia.de - Lederpedia - Lederwiki - Lederlexikon

Eine freie Enzyklopädie und Informationsseite über Leder, Ledertechnik, Lederbegriffe, Lederpflege, Lederreinigung, Lederverarbeitung, Lederherstellung und Ledertechnologie